The WELL Building Standard is a certification introduced in 2014 by the International WELL Building Institute (IWBI) and administered by Green Business Certification Inc. (GBCI).

Unlike LEED (Leadership in Energy and Environmental Design®), which is geared towards environmental sustainability, WELL focuses on the health and well-being of the occupants.

It is a roadmap for creating and certifying spaces that promote human health and well-being and sets out pathways to achieve this.

What is the WELL building standard?

WELL provides a framework around human health, well-being, productivity, and sustainability with a clear focus on the user occupier. It includes objectives and compliance requirements for a building’s owners and other stakeholders.

WELL V1 covers seven health basics: air, water, food, lighting, fitness, comfort, and mind, for all types of buildings, including commercial, retail, industrial, residential, and restaurant offices.

WELL V2 was published in 2018, incorporating best practices from over 1,000 existing WELL projects and human health research.

The categories went from seven to ten:

- Air

- Water

- Nourishment

- Lighting

- Movement

- Thermal comfort

- Sound

- Materials

- Mind

- Community.

Each WELL concept includes features that address design, culture, operational policies and maintenance protocols. When implemented, these specific changes can help any building or organization better serve the health of its customers, employees and visitors.

How is the WELL standard obtained?

Features include both preconditions and optimizations. To successfully obtain this certification, the preconditions and weighted optimizations must be accomplished:

1. Universal preconditions

WELL describes a set of universal preconditions that projects must meet in order to be certified. These are mandatory characteristics that are considered indispensable for human health in indoor environments.

2. Flexible optimizations

Flexible optimizations are features that demonstrate additional achievements for the WELL building standard v2 certification. Although is not mandatory, projects can earn additional recognition for higher levels of certification (bronze, silver, gold, and platinum).

3. Verification of actions

Certification of a project is calculated using an overall WELL score that encompasses completion of project preconditions and optimizations. Verification is done through an on-site assessment by a WELL assessor. Verification is complete once all respective documents have been submitted and approved.

If you want more information about how this certification works, we suggest you to visit the WELL Certified Home page.

Optimize efforts in the certification process

A good way to optimise efforts to obtain a WELL certification is to use a real-time indoor air quality meter.

This device can be a great support tool for architects, designers, sustainability advisors, builders and WELL project managers to know the air quality prior to the verification process.

On-site performance testing, real-time reporting, and continuous monitoring are requirements for getting WELL certification. Having access to project air quality data prior to performance testing can save time and money.

Measuring indoor pollutant levels helps project owners better understand any indoor environmental weaknesses.

Under the fundamental air quality preconditions, projects must meet certain thresholds for particulate matter PM and organic gases, both verified through performance testing, and must also implement an air quality monitoring system, verified through continuous data reporting.

Besides, to satisfy the thermal comfort precondition, a project must demonstrate its ability to control temperature and humidity, which is very easy to control through such devices.

In addition, section A08 of the WELL standard awards points for continuous air quality monitoring.

There are devices that have integrated WiFi, allowing them to connect to the cloud and collect valuable data that will help in decision making.

Indoor air quality in the WELL Building Standard

The first concept under the WELL standard is air. To improve and achieve good indoor air quality, it proposes various strategies and special attention should be paid to the following parameters

Particulate Matter (PM)

Compliance with the thresholds established by the WELL standard for particulate matter in general interior spaces and construction projects.

- Preconditions: A01 (Fundamental Air Quality)

- Optimizations: A05 (Improved Air Quality) and A12 (Air Filtration)

Some features of WELL focus on reducing particulate levels. IWBI requires WELL applicants to meet strict PM2.5 and PM10 thresholds.

These thresholds are based on standards of the World Health Organization (WHO) and other regulatory bodies such as the US Environmental Protection Agency (EPA), and are usually very specific, for example, one aspect of obtaining the Fundamental Precondition of Air Quality (A01).

Volatile Organic Compounds (VOCs)

Register harmful chemicals and toxins, also known as volatile organic compounds (VOCs) to make sure they meet permitted concentrations.

- Preconditions: A01 (Fundamental Air Quality)

- Optimizations: A05 (Improved Air Quality) and A13 (Active VOC Control)

Building materials and items such as carpets, furniture, fabrics, cleaning products, adhesives, solvents, and many more everyday cleaning supplies are known to emit volatile organic compounds (VOCs).

VOCs can be easily inhaled through the lungs. Its regular exposure can cause irritation to the eyes, throat, nose, and skin, and prolonged exposure has been linked to outbreaks of eczema, hives, allergies, leukemia, and damage to the kidneys, liver, and central nervous system.

WELL includes features that require effort to reduce VOC levels. Like particulate matter, IWBI has determined specific thresholds for VOC levels based on recommendations from leading healthcare organizations.

Carbon dioxide (CO2)

Building ventilation management to improve employee productivity and general well-being.

- Preconditions: A03 (ventilation efficiency)

- Optimizations: A06 (improved ventilation)

WELL emphasizes proper building ventilation to keep indoor air quality at healthy levels. Spaces that are not well ventilated can cause their occupants to experience a variety of symptoms, often called sick building syndrome (SBS), such as headaches, fatigue, dizziness, nausea, coughing, sneezing, shortness of breath, and eyes, nose, throat and skin irritation.

Due to its profound impact on human health, WELL includes features that specifically focus on a building’s ability to provide a healthy amount of fresh air and ventilation. How exactly can ventilation be measured and tested? IWBI has found a simple solution: through carbon dioxide.

WELL states that, since it is difficult to test all potential pollutants in a space, carbon dioxide is used as a substitute for other indoor pollutants. Particularly stale air will fill with carbon dioxide, especially in high-occupancy spaces, and carbon dioxide itself can reduce productivity and cause drowsiness.

WELL features like Enhanced Ventilation (A06) require CO2 levels below 900ppm.

Humidity

Control of humidity levels for construction projects to prevent the growth of microbes and mold.

- Preconditions: A04 (Construction Management Pollution)

- Optimizations: A14 (Control of mold and microbes)

Humidity levels must be kept in a precise balance to avoid damage to both the building and the health of the occupants. Too high a humidity can cause discomfort to the occupants and can also cause mold and mildew growth, which affects allergies. Too low a humidity can cause occupants to experience eye, nose, skin and throat irritation.

WELL focuses on the humidity in some of its features to ensure that the project in question is not prone to mold growth; To obtain the Optimization of Microbe and Mold Control (A14), IWBI observes the indoor relative humidity levels to make sure they do not exceed 60%.

Temperature

Temperature

Maintenance of interior comfort:

- Precondition: A04 (Construction Management Pollution)

- All preconditions and optimizations for thermal comfort (T01-T07)

Temperature is another factor that affects the health and productivity of building occupants.

However, this specification is not in the category of air, but of thermal comfort. The use of a device such as Nanoenvi IAQ with a temperature sensor helps to guarantee thermally comfortable indoor environments.

Well Building Standard IAQ Requirements

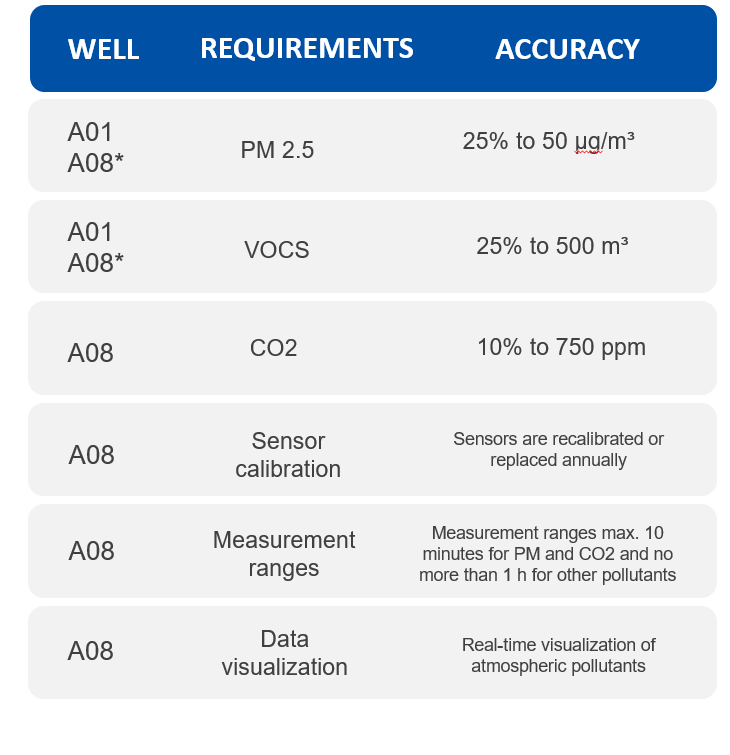

This summary table shows the parameters required by WELL, their required accuracy:

Why monitor indoor air quality in a building with the WELL Building Standard?

Air quality monitoring itself has an important weight in the WELL Building Standard certification score in Spain.

- Optimisation: A08 (Air quality monitoring and awareness).

IWBI developed Optimisation A08 (Air quality monitoring and awareness) in an effort to encourage projects to become advocates for maintaining and spreading awareness of indoor air quality.

This optimisation rewards air quality monitoring with additional points that are easy to obtain if the project’s air quality device meets specific requirements: five enterprise-level self-calibrating sensors and easily accessible data stored in a dashboard.